The Turbo Era in Formula 1 refers to a period in F1 racing from the late 1970s to the late 1980s when turbocharged engines were widely used. This era saw a dramatic increase in horsepower outputs from F1 cars, with power figures more than doubling from around 500hp in the normally aspirated V8/V12 engines in the early 1970s to over 1000hp by the mid-1980s with turbocharged engines.

The adoption of turbocharging technology in F1 was a breakthrough that allowed smaller and more fuel-efficient engines to achieve power outputs on par with or exceeding the large displacement atmospheric engines that preceded them. Turbocharged engines brought about a new dimension of performance – but also new challenges in taming their formidable power while preserving reliability and driver safety.

Pioneering Phase of the Turbo Era in F1

The earliest turbocharged engines in F1 racing first appeared in the 1977 season, pioneered by the Renault team though with limited initial success. Over the next few years, other manufacturers began experimenting with turbo power as regulations were relaxed to permit their use.

The early turbocharged F1 engines were temperamental and lacked drivability, afflicted by turbo lag at low rpm and prone to failures under the demands of racing. However, with rapid engine development addressing turbo lag and improving performance, their fuel efficiency and power delivery characteristics made them clearly superior to normally aspirated engines.

Early Development of Turbochargers

The concept of turbocharging dates back to the early 20th century, but it wasn’t until the 1970s that turbochargers became a crucial component in Formula 1 engines. The first turbocharged engine was developed by Alfred Büchi, a Swiss engineer, in 1905. Büchi’s innovation laid the groundwork for future advancements, but it took several decades for the technology to mature and find its place in high-performance applications like F1.

First Turbocharged Engine

The breakthrough moment for turbocharged engines in F1 came with the debut of the Renault RS01 in 1977. Designed by François Castaing, this pioneering engine produced over 500 horsepower, a remarkable feat for its time. The RS01’s success demonstrated the potential of turbocharging, encouraging other teams to explore this technology. By the early 1980s, turbocharged engines had become the standard in F1, revolutionizing the sport with their superior power and efficiency.

The Dominance of Turbo Power

By the 1982 season, turbocharged engines demonstrated clear dominance, and by the mid-1980s were adopted by practically all teams on the grid. The horsepower figures reached unprecendented levels exceeding 1300hp in qualifying trim – though races were run at reduced power.

The turbo era saw some epic championship battles between legendary drivers powered by these beasts – like Nelson Piquet, Niki Lauda, Alain Prost and Ayrton Senna. Manufacturers like Ferrari, BMW, Porsche, Honda and TAG-Porsche exploited turbo power in this arms race for performance.

Safety concerns and escalating speeds, costs and power outputs eventually led to the decline of turbochargers by 1989. However, the turbo era left an indelible mark on Formula 1 – establishing the superiority of forced induction in motorsports.

Brief History of Formula 1 and the Introduction of Turbocharged Engines

The Atmospheric Engine Era of F1

Formula 1 racing traces its early roots to the European racing scene of the 1920s and 1930s. Grand Prix racing grew in popularity between the 1930s to 1950s with legendary drivers like Juan Manuel Fangio dominating the sport.

The early decades featured atmospheric engines progressing from large capacity supercharged beasts in Auto Union and Mercedes silver arrows in the 1930s, to nimbler 1.5 liter naturally aspirated engines in the 1950s.

The Formula 1 World Championship was established in 1950 which laid down engine specifications and limited engine size to stay close to road-going technology. The 1950s F1 cars used compact Inline-4 engines displacing around 2.5 liters, producing 180-200 hp, which grew to 2.5 liter Inline-4s making 220-240 hp by 1960.

The Rise of V8 and V12 Engines

In 1961, the engine capacity limit was increased to 1.5 liters, spurring British teams to adopt lightweight compact V8 designs producing around 190 hp initially, which was boosted to around 270 hp by the late 1960s with ever improving chassis, tire and engine designs. The brave Cosworth DFV V8 powered many cars through the 60s and early 70s.

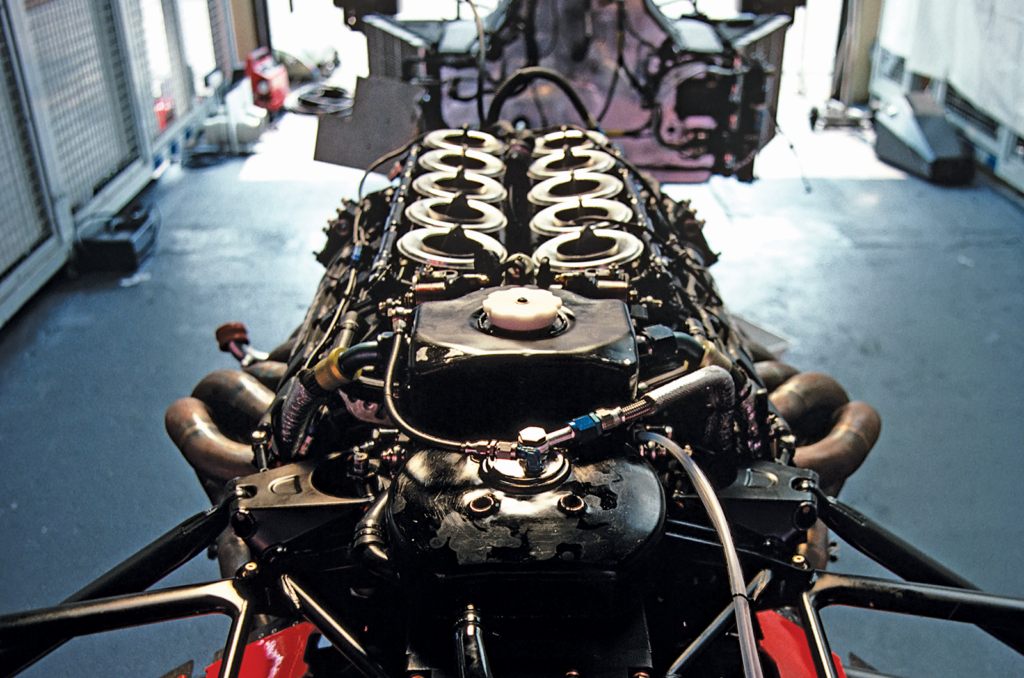

The mid 1970s saw atmospheric racing engines reaching new peaks in specific output through engineering ingenuity – like the tiny but sonorous Ferrari Flat-12 producing 520hp from just 3 liters. However, extracted air and fuel were approaching physical limits in large engines without forced induction.

Emergence of Forced Induction

With engine capacity frozen, the only route to expand power was through pressure charging. Following a decade of research, Renault persuaded the FIA to permit turbocharged engines in F1, heralding a new era of forced induction Grand Prix racing from 1977 onwards.

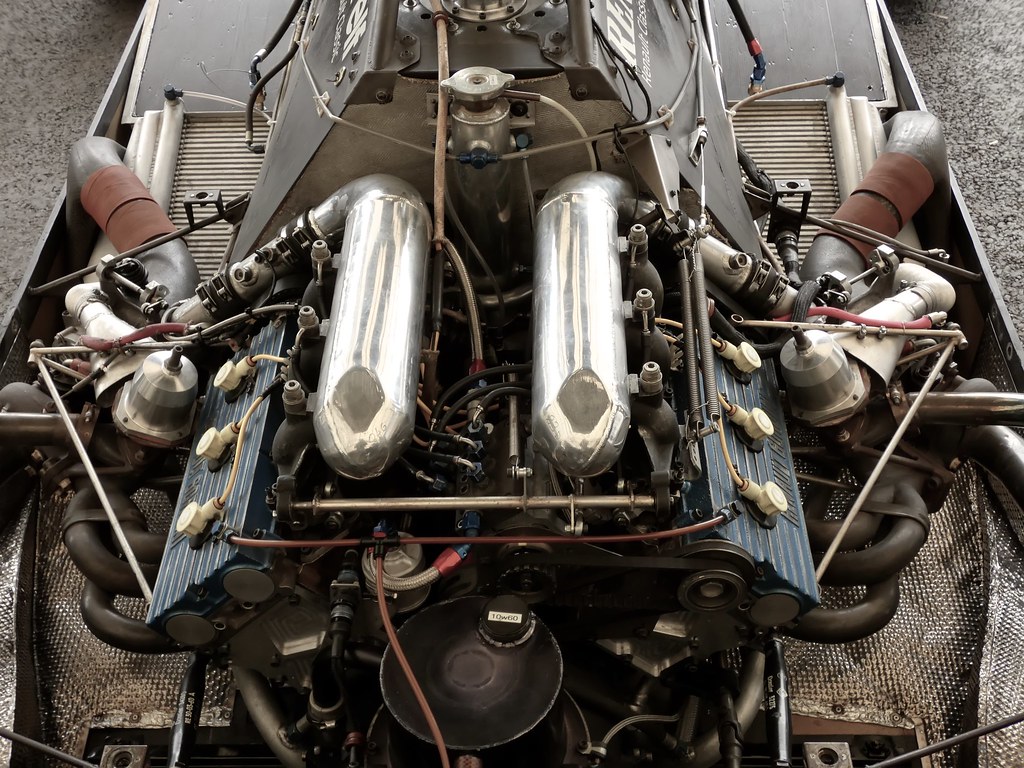

Initially limited to 1.5 bar boost pressure due to reliability concerns, the FIA slowly relaxed rules through the next decade. Along with improved metallurgy, this allowed mindboggling boost pressures up to 4 bar on bespoke turbocharged 1.5 liter V6 engines ultimately producing over 1300 hp in race trim by 1986!

Explanation of Turbochargers and Their Role in Engine Evolution

A turbocharger allows a smaller engine to punch above its weight by greatly increasing power output through forced induction – packing more air into the engine to burn more fuel.

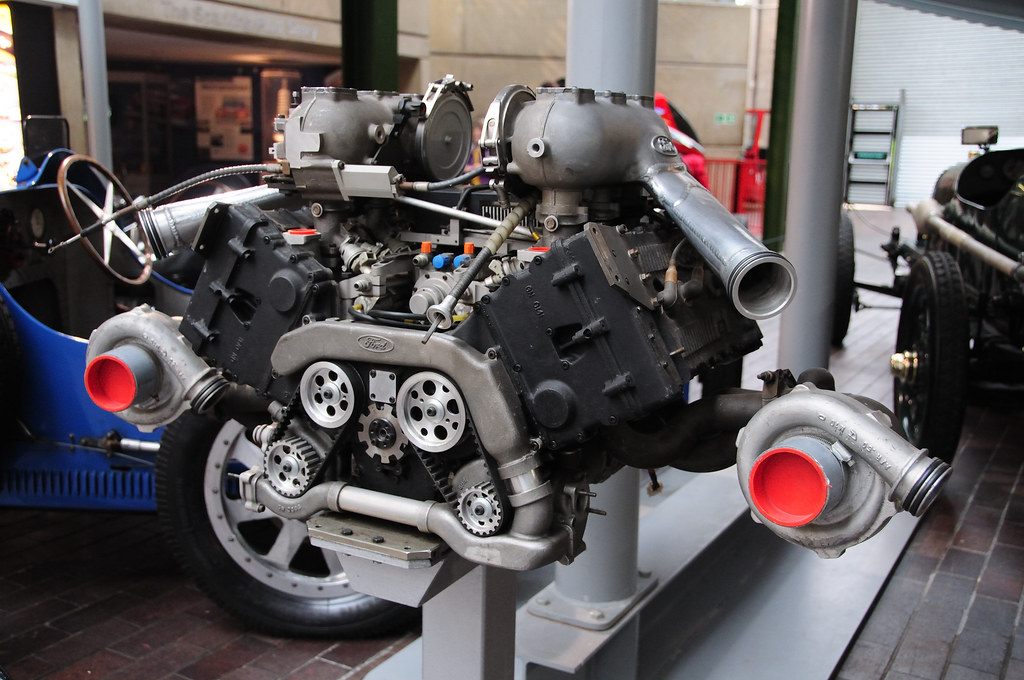

It comprises a turbine and compressor connected by a shared shaft. The turbine is spun by the engine’s exhaust gases while the compressor pressurizes intake air into the engine via an intercooler. The turbine can spin at over 100,000 rpm, driven by peak exhaust temperatures exceeding 700°C in an F1 engine!

Technology of Turbocharged Engines

The operating principle of a turbo seems simple enough but engineering a reliable compact unit that can survive at the extremes of temperature and rotational forces involved requires remarkable precision and exotic metallurgy – particularly for motorsports applications.

While early turbo engines suffered from throttle lag at lower rpm due to turbine inertia, the switch to smaller V6 layouts with electronically controlled wastegates and blowoff valves helped make turbo power more drivable. Smaller turbos also reduced rotational inertia enabling quicker spool up.

Intercoolers help cool compressed intake air to increase its density for more power. Specialized lubricants and bearing technologies reduce friction while resisting immense heat. And turbo wastegates bleed off excess exhaust when maximum boost is reached.

Benefits of Turbocharging IN F1 CAR

Turbochargers confer several benefits that made them attractive for motorsports:

1. More power from a smaller, lighter engine: Turbocharging a 1.5 liter V6 to match a 3 liter V8

2. Improved fuel efficiency due to higher volumetric efficiency

3. Packaging benefits from smaller engines leaving more space for ground effects aerodynamics

4. Ability to vary power output dynamically by adjusting boost pressure

The Impact of Regulatory Changes on the Adoption of Turbo Technology

The regulatory landscape of the late 1970s played a key role in enabling turbocharged engines in Formula 1. Rule changes opened the door for forced induction while later restrictions modulated their development.

Regulations Permitting Turbos

In the early 1970s, the F1 rules limited engines to just 3 liters displacement with atmospheric induction, heavily favoring the 12-cylinder layout. Seeking a way to allow greater innovation, the FIA decided to freeze maximum capacity at this limit but permit forced induction from 1976 onwards.

Renault lobbied hard for this change which benefited their compact but powerful turbocharged unit in development since 1968. Turbo development was still restricted – limited to just 1.5 bar (21.7 psi) boost pressure initially, later raised to 2.5 bar and 4 bar through the 80s.

Banning Turbos and Traction Control

While turbos led the way on power, their extreme performance also raised safety concerns. By 1988 speeds were becoming dangerously high, with turbos blamed for making cars trickier to drive. Fatal crashes increased pressure to ban turbos.

So in 1989, the FIA legislated the end of the turbo era – limiting cars to 3.5 liter naturally aspirated engines reducing power by over 200hp. Electronic driver aids like traction control were also banned to put driver skill ahead of technology.

This regulatory see-saw demonstrates how rules play a key role in shaping F1 technology. The turbo proved so effective at extracting power that its own success led to it being regulated out of existence fearing where escalating power might lead.

Turbocharged engines offer superior power and efficiency compared to conventional naturally aspirated engines by using exhaust gases to force more air into the combustion chamber. Let’s examine the inner workings of a turbo system.

The Turbocharger Unit

A turbocharger comprises two linked rotating assemblies – the turbine and compressor – sharing a common shaft and housing. The turbine is positioned in the exhaust stream while the compressor sits within the intake system.

The turbine has angled veins which force it to spin when hit by fast-moving exhaust gases. The compressor features fan-like blades that centrifugally accelerate intake air. Since both are connected by a shaft, the turbine spins the compressor when exhaust velocity is high.

Forced Induction of Denser Air

The spinning compressor unit packs more air molecules into the engine’s cylinders. This denser intake charge contains more oxygen atoms available for burning fuel during combustion.

With up to double the air density, nearly 100% more fuel can be burnt. This greatly boosts the engine’s volumetric efficiency and power output compared to natural aspiration.

Intercooling Charge Air

Compressing air raises its temperature. Hotter air expands and loses density. So most turbo cars employ an intercooler between compressor and cylinders to remove heat from this pressurized intake air.

Cooling the charged air maintains its density for even more oxygen packed into the chamber, further boosting power. It also reduces the risk of pre-ignition and detonation.

Managing Turbo Boost Pressures

A wastegate valve regulates exhaust gases reaching the turbo turbine wheel. When intake pressure reaches a preset limit, it bleeds off excess exhaust gases bypassing the turbo. This prevents over-speeding and controls maximum boost pressure.

Smart electronic boost controllers alter wastegate opening based on throttle position and rpm to reduce lag before peak boost is reached. Blow-off valves release pressure spikes when lifting off throttle for stability.

The Performance Edge Offered by Turbochargers

Turbochargers enhance engine performance by:

Greater Peak Power

Turbocharging allowed 1.5 liter F1 V6 engines to achieve astounding power outputs over 1300 hp by 1986 – nearly triple the contemporary normally aspirated 3 liter Formula 1 V8s!

This enormous power edge was achieved by pressurizing the tiny engine with over 2.5 bar (36 psi) of boost. Such astronomical charging pressures were only possible through precision ball bearing turbos and strengthened engine internals.

Wider Power Band

While early turbos were plagued by throttle lag before peak boost arrived, fuel metering, smaller turbines and exotic alloys reduced this deficiency through the 1980s. Smaller turbos spun up faster, delivering stronger mid-range punch.

This widened the usable rev range while raising peak power figures – creating an intoxicating mix of drivability and top end rush suiting the demands of racing.

Superior Fuel Efficiency

Turbocharging improves the engine’s volumetric efficiency allowing it to burn more fuel with the same engine capacity and rpm. By cramming over 100% more air into every stroke, nearly twice as much fuel can be combusted.

This means a 1.5 liter turbo six could match a 3 liter atmospheric eight on power while using much less fuel – a crucial edge for endurance racing.

Packaging and Weight Reduction

The compact dimensions of turbocharged engines allowed engineers more space to experiment with ground effects aerodynamics for increased cornering grip. Vehicle weight distribution also improved with smaller lighter engines compared to bulky atmo V8s and V12s.

Together with the advent of slick tyres and wings, turbo power synergized with chassis advancements – producing the most impressive leap in performance in F1 history through the 1980s.

Highlighting Successful Formula 1 Teams and Drivers in the turbo era in f1

The F1 Turbo Era was an arms race dominated by works manufacturer teams and legendary drivers who mastered the blend of outrageous power and tricky handling, with notable cars like the Renault Turbo RS01 and the McLaren Honda. Let’s look at some famous names who emerged as champions.

Nelson Piquet and Brabham-BMW

Nelson Piquet was the first F1 champion of the turbo era, winning back-to-back titles in 1981 and 1983 driving for Bernie Ecclestone’s Brabham team, powered by compact 1.5 liter BMW inline 4-cylinder engines making a scintillating 1300 hp in qualifying.

The fiery Brazilian tamed the laggy early BMW turbos which matched traditional V8s on pace but initially lacked their throttle response. Brabham’s clever engineers coaxed more controllable power from BMW’s small but sturdy powerplants.

Alain Prost – Fastest Man on Earth

Blessed with phenomenal sensitivity behind the wheel, Alain Prost won the F1 title 4 times through the turbo era mastering first Renault then McLaren turbos on the way to becoming the series’ most prolific winner and “The Professor” of racecraft excellence and technical finesse.

His clinical precision and technical acuity enabled him to extract every fraction of advantage from the high strung machines, smoothing power delivery with feather inputs other dared not attempt. Famous for his economy of motion and intellectual approach, Prost dazzled with metronomic laps approaching qualifying pace for entire races.

Ayrton Senna – Mercurial Genius

If Prost represented the zenith of cold calculated precision, arch-rival Ayrton Senna demonstrated a more heart-on-sleeve flamboyance coupled to raw pace few have matched before or since. His mesmerizing qualifying laps left teammates seconds adrift, wringing every molecule of speed from the cars through sheer audacity and will.

Senna first displayed precocious talent hustling Toleman’s turbo to 2nd at Monaco in teeming rain. His agile mind and lightning responses eventually carried him to 3 world crowns with McLaren-Honda as their ferocious rivalry wrote F1 legend.

Major Wins and Championships Fueled by Turbo Technology

Turbocharged engines utterly dominated Grand Prix racing for a decade. Let’s look back on some memorable championship victories and race wins they powered to in F1 lore. The performance of a turbo car, compared to naturally aspirated vehicles, is notable for its superior speed, torque, and handling characteristics.

Renault’s Breakthrough Win – Dijon 1979

Renault recorded a breakthrough maiden win with its small 1.5 liter turbo V6 in the 1979 French Grand Prix at Dijon. Jean-Pierre Jabouille made history fending off Gilles Villeneuve’s Ferrari before the engine expired in a cloud of smoke. A landmark moment as forced induction arrived in F1.

Turbocharged Renault and Ferrari during the 1979 Dijon Grand Prix

Brabham Back on Top – Brazilian GP 1983

Over a decade after founder Jack Brabham’s titles, Nelson Piquet delivered Brabham their first turbocharged GP win in 1983, taming searing heat and Osella’s Eddie Cheever to claim the team’s first of two straight drivers’ crowns.

Prost starts McLaren Legend – 1985 Monaco GP

Alain Prost earned McLaren its first victory with the Porsche-built TAG turbo V6 at the 1985 Monaco GP, passing Michele Alboreto’s Ferrari late in the race. It heralded a golden age with multiple titles for driver and constructor to follow over the decade with Senna.

Mansell Mania – British GP 1987

Nigel Mansell thrilled home crowds charging from 4th to 1st on the opening lap at 1987’s British GP at Silverstone, aggressively passing Piquet and Senna before walking away to claim the Williams-Honda. His move around the outside of the fearsomely fast Stowe corner is the stuff of legend.

The above victories highlight famous milestones and moments etched into motorsports history books courtesy of 1000+ hp turbocharged engines during their decade of domination in Formula 1. Their legacy endures in fan memories and technical DNA that continues to accelerate racing evolution today. The turbo era was a magical flashpoint that will likely never be repeated.

The Reliability Concerns of Turbo Engines IN FORMULA 1

While turbochargers unleashed enormous power from small engines, this performance came at the expense of formidable reliability challenges in the high stress environment of Formula 1 racing.

Extreme Operating Conditions

The turbocharger unit faces some of the most punishing conditions seen in motorsport. Peak exhaust temperatures can exceed 700°C spinning the turbine at over 100,000 rpm. This places immense centrifugal loads on the CHRA (center housing rotating assembly) bearings.

The noted engine builder Keith Duckworth famously termed turbochargers as “mangles that run on lard” – highlighting their tendency to devour themselves if not adequately lubricated, cooled or assembled to near perfection.

Early Teething Issues

When turbos debuted in 1977, metallurgical science struggled to resist such brutal heat and rotational forces. Moreover, the primitive bespoke designs being pioneered lacked the benefit of data and operating experience in extremes of racing use.

Consequently, early turbo engines suffered an appalling lack of dependability. It was common to see units expire in billowing smoke after just a handful of racing laps due to cracked manifold welds, bearing failures or burst lubrication pipes.

Through the next decade, even top teams like Ferrari and BMW were plagued by only finishing half their races – such was the fine line between outrageous power and terminal mechanical disaster. Vast improvements in materials science and tighter manufacturing tolerances were needed before turbos became remotely reliable.

Managing Monster Torque

As boost pressures grew to over 2.5 bar on 1.5 liter engines, torque outputs skyrocketed to levels that could easily overwhelm chassis and drivetrains designed for lighter atmospheric units. Engines had to be meticulously mapped to deliver a smooth and progressive power band. The smallest hesitation or spike in delivery would snap half-shafts, strip gears or light up tires uncontrollably.

After mastering the engine, racers still faced the daunting task of hooking up prodigious power through narrow treaded tires on twisty circuits with no electronic assistance – and often no margin for error at 300kph!

Safety Debates and Regulatory Conflicts

Turbo engines allowed small economical cars to very nearly match the ferocious power outputs traditionally limited to big multi-liter engines in exotic thoroughbred racers – but without decades of development. Only stringent rules contained runaway power escalation but at the cost of conflict between regulators and manufacturers.

Attempts to Restrict Escalating Power

When Renault’s lobbying opened the turbo Pandora’s box, some foresaw issues in containing power. So the FIA strictly limited boost pressure to just 1.5 bar initially. But with each successive season, teams successfully lobbied for relaxed rules as reliability improved.

First the FIA raised permitted boost to 2.5 bar, then to staggering levels exceeding 4 bar! Peak power doubled from just over 500 hp in 1977 to an intense 1100 hp by 1986. With teams like BMW exploring twin-turbo ideas, many believed the madness had to be reined in before teams exceeded the capabilities of drivers or circuits.

Banning Turbos and Traction Control

After a spate of horrific high profile crashes from 1982-87 involving turbo cars, the FIA finally intervened ahead of 1989 by banning turbos and restricted engines to naturally aspirated 3.5 liter units with reduced power. F1 cars suddenly shed over 200 hp – the first deliberate power reduction in the sport’s history.

This led to accusations that the FIA changed rules solely to cut costs and advantage non-turbo teams unable to match the level of financial and technological commitment needed to exploit forced induction. Indeed Williams alone had a $100 million / year budget tailored around turbo success.

Safety Issues Stemming from Turbocharged Engines

While turbos delivered exponentially greater power from liter-for-liter engine sizes, this overwhelming performance came at the expense of increased danger both from speed and challenges in harnessing their performance.

Compromised Handling and Aerodynamics

Early turbo engines usually retained traditional rear-wheel-drive layouts. But the compressed powerband and peakier torque delivery made traction more difficult without modern aids like traction control. Lighter smaller chassis using wings for downforce also lacked ballast and wheelbase length to stabilize at ever higher cornering speeds.

Together with narrow treaded tires designed for lower powered cars, drivers constantly battled snap oversteer, wheelspin on corner exits and knife-edge handling exacerbated by over 1000 hp overwhelming suspension geometry optimized for atmospheric engines.

Power Too Extreme for Downforce Levels

While early turbo engines leapfrogged peak power output, it took time for chassis and aerodynamics to catch up. So during the early 80s, F1 pilots drove cars with nearly double the power of their predecessors but scarcely any more grip to harness it.

With tiny contact patches from narrow tires pushing slip angles to the limits, even brief spikes of wheelspin saw cars rotating from optimal racing lines – losing time or potentially control. Keeping turbos smoothly delivering maximum torque without lag or surge was critical.

Uncharted Territory of Speed

The turbo era marked the last time F1 machines could substantially exceed racetrack design limits. Shorter wheelbase cars struggled to stabilize at over 190 mph down straights as designers lacked data for creating stability or optimizing braking and suspension at such velocities.

Wide speed differentials between cars on power and grip circuits led to controversial decisions to add chicanes at iconic circuits like Monza and vast runoff areas which diluted track challenge according to purists.

Noteworthy Incidents and Safety Enhancements

The unprecedented performance levels achieved by 1000+ hp turbo F1 cars of the 1980s led to renewed scrutiny on driver safety as horrific accidents mounted. Let’s look back on some key incidents and the safety improvements they spurred.

1982 Belgian GP Weekend – Multiple Fatalities

The perilous razor edge of turbo power was cruelly highlighted at 1982’s Belgian GP race weekend where a succession of horrendous crashes saw 3 drivers lose lives to accidents in practice alone, while champion-to-be Didier Pironi suffered career ending injuries in the race itself.

Fatal impacts suffered by Gilles Villeneuve and Riccardo Paletti saw the Grand Prix Drivers’ Association demand slowed cars, only defused after teams devised less volatile qualifying power levels.

Imola 1994 – Death of Ayrton Senna

While no direct fault of the earlier turbo era, the shocking loss of legend Ayrton Senna in 1994 (alongside Roland Ratzenberger) finally compelled sweeping maneuver at addressing driver safety. The Professor Sid Watkins led reform demanded improvements from helmet design to crash structures and circuit interventions which ushered in the safer F1 seen in subsequent decades.

Advanced Composite Monocoques

While the turbo engines and active suspension received more headlines through the 1980s, perhaps the most meaningful progress was made in chassis design as teams transitioned from aluminum sheet or honeycomb semi-monocoques to advanced composites layups over Nomex cores that increased rigidity and survival cell integrity.

Pioneered by McLaren, this construction method proved universally effective at managing crash energy absorption and securing the driving compartment to preserve life, even in violent collisions. By 1986 all teams adopted carbon fiber tubs which strengthened cockpit integrity.

Reasons for the Decline of Turbocharged Engines IN FORMULA 1 in the 80s and 90s

By 1989, the extreme performance levels and escalating costs of turbocharged Formula 1 engines led the FIA to ban forced induction in the interests of cost control and safety.

Runaway Power and Speeds

Turbo engines saw nearly a threefold power increase through the 1980s. By 1986-87, F1 cars were averaging over 195 mph with BMW’s 1500+ hp qualifying engines reported to touch 230 mph at Monza. With drivers barely containing performance, the FIA feared fatal consequences.

Spiraling Costs

Exploiting the full potential of turbo engines required extensive metallurgy research, exotic materials, bespoke machining tools and facilities costing tens of millions yearly.

As pressure to win championships intensified in F1’s ultra-competitive ecosystem, manufacturers poured hundreds of millions constructing entire engine programs around turbo success. Williams alone spent over $100 million chasing the 1987 title.

Costs were deemed unsustainable, pricing smaller privateers out of contention. Non-factory outfits lacking turbo pedigree essentially became non-competitive against the turbo powerhouses of Ferrari, BMW, Honda and Porsche.

Ban on Turbos and Traction Control

Citing runway speeds, costs and safety concerns from 1982-1987’s spate of horrific crashes, the FIA banned forced induction for 1989 while restricting engines to 3.5 liter atmo units stripping over 200 hp. Electronic driver aids were also prohibited putting driver skill ahead of technology.

To veterans, this rule change essentially punished innovation to artificially create closer competition between well-funded factory turbo teams and the struggling privateers relying on cheap tuner engines.

The Impact of the Turbo Era IN FORMULA 1 ON MODERN CARS

Though brief, the turbo decade left an indelible print on Grand Prix racing whose DNA persists in contemporary F1 machines.

Last Non-Electronic Era

The turbo era marked the finale of mechanical dependency before electronics infiltrated car control. Giants like Prost and Senna honed an intimacy with machine dynamics impossible in today’s digitally filtered environment saturated with riding aids that detach drivers from absolute focus.

Surviving over 1000 horsepower without electronic stability or launch control trained razor reflexes and car sensitivity most consider unattainable today. The turbo era birthed driving legends.

Apex of Engine Performance

Turbo engines pushed the boundaries of specific output to extremes never repeated. Well over 1500 hp qualifying engines exceeded 220 hp per liter from relatively narrow 120° vee angles – thermodynamic magic never recaptured since.

Engine design was elevated almost into an art form in extracting such prolific power from miniscule displacements without self-destruction. Materials science advanced considerably under the crucible of turbo extremes.

Safety Improvements

The accidents of 1982-87 shook F1 deeply but compelled meaningful safety review from helmet specs to medical protocols and circuit interventions establishing a template for continuous improvement that has seen driver safety increase exponentially in subsequent decades.

The dangers revealed by turbo power’s outright performance at least highlighted risks that demanded remedy for long term advancement. Turbo absolutes provided a roadmap to managing limits.

The Return of Turbocharged Engines in Modern F1

Rule Changes Welcome Turbos Back from 2014

In 2014, sweeping F1 engine regulation changes marking the hybrid era reintroduced turbocharging paired with extensive energy recovery systems (ERS) for enhanced efficiency and renewable performance from electric drive integrating turbo-compounded internal combustion.

Now more an integrated power unit than engine alone, these marvels of hybridized turbocharging recapture the intoxicating rush of ballistic power paired to high-tech future-gazing designs undreamt of in the 80s.

Extreme Specs Extract Unprecedented Efficiency

Ushering a new generation of power, today’s 1.6 liter V6 turbos achieve thermal efficiency over 50% – the highest of any road-car application – thanks to mega 125,000 rpm compressor speeds, direct injection exceeding 500 bar pressure and intricate divided twin-scroll exhaust manifolds.

Deploying multiple energy recovery methods, braking heat also generates electric power réapportioned to boost output. Such complex integration ushers new directions chasing the most from every drop of precious fuel.

The Combination of Turbo and Hybrid Technologies in Today’s F1

Modern F1 power units showcase phenomenal hybridized forced induction powertrains at the apex of internal combustion evolution. When comparing turbo era F1 cars to modern F1 vehicles, the differences in horsepower and aerodynamics become evident, sparking debates on which era’s car would excel in a time attack session.

Turbocharger Assistance

A single turbocharger boosts air density into the 1.6 liter V6 through an unlimited boost strategy optimized across the rev range for transient response. Exotic alloys cope with scorching 1300+ degree exhaust gas temperatures spinning turbines beyond 125,000 rpm!

Complementary Hybrid Systems

In addition to turbo mechanics, these motors generate electric power from multiple recovery systems, then redeploy this harvested energy to boost performance.

The MGU-K (Motor Generator Unit – Kinetic) recovers waste heat energy normally lost during braking by converting clamping disks into generator rotors.

The MGU-H (Motor Generator Unit – Heat) scavenges exhaust turbine excess unavailable for compressor rotation into battery drive.complementing the MGU-K.

This harvested electricity can then be channeled to supplement turbo boosting, extend maximum power durations or optimize energy deployment.

Futuristic Performance from Fossil Fuels

Formula 1’s state-of-the-art hybrid turbocharged power units hint at the next generation of road going sports cars – leveraging electric augmentation to unleash phenomenal pace from downsized forced induction engines emitting a fraction of conventional atmospheric pollutants.

These drivetrains showcase the synergetic possibilities of synthesized hybridized propulsion when chasing maximum endeavor. Their specs represent motoring’s highest echelons.

Role of Internal Combustion Engine in Turbocharged Engines

The internal combustion engine is the heart of any turbocharged system, playing a pivotal role in its operation. In a turbocharged engine, the exhaust gases generated by the internal combustion process are harnessed to drive the turbocharger. This turbocharger compresses the intake air, forcing more oxygen into the engine’s cylinders. The result is a significant increase in power output and efficiency, as the engine can burn more fuel and produce more power from the same displacement.

Internal Combustion Engine Evolution

Since the introduction of turbocharged engines in F1, the internal combustion engine has undergone continuous evolution. Modern F1 engines are marvels of engineering, combining high power output with remarkable efficiency. The integration of hybrid electric systems has further enhanced their performance, allowing for energy recovery and reuse. These advancements have made contemporary F1 engines not only more powerful but also more environmentally friendly, setting new standards in automotive engineering.

Motor Generator Unit (MGU) and Turbo Cars

In the realm of modern F1, the Motor Generator Unit (MGU) has become an indispensable component. The MGU is an electric motor that recovers energy from the engine’s exhaust gases and converts it into electrical energy. This recovered energy is then used to power the car’s electric motor, providing an additional boost to the wheels and enhancing overall performance.

Motor Generator Unit (MGU)

The MGU is a sophisticated system comprising several key components, including an electric motor, a generator, and a power electronics system. It is capable of recovering up to 160 horsepower from the engine’s exhaust gases, which is then used to power the car’s electric motor. This not only improves the car’s performance but also its efficiency, making the MGU a critical element in the modern F1 powertrain. By harnessing the energy that would otherwise be wasted, the MGU plays a crucial role in the pursuit of maximum efficiency and performance in today’s turbocharged F1 cars.

Conclusion

The Profound Impact of the Turbo Era on Formula 1

While brief, the 1980s turbo decade fundamentally transformed Formula 1 – doubling power outputs within 10 years and establishing forced induction as the unambiguous route to preeminence in motorsports internal combustion engine design for the foreseeable future.

Its legacy endures through the drivers it immortalized, safety milestones it necessitated and technical boundaries it expanded for Maxwell Demon aspirations.

The Potential Future of Turbocharging in Motorsports

Today’s Formula 1 hybrid turbocharged V6 units highlight exciting pathways to ultra efficiency by harvesting wasted energy through electric regeneration and fusing this bounty to amplify turbocharging’s fundamentals.

Road transport CO2 emission targets will further prioritize forced induction assigned power nodes optimized for right-sizing transient loads through smart electrification.

As environmental constraints tighten, physics realities dictate smaller engines must extract more work from less displacement without sacrificing performance expectations. Formula 1 continues pioneering these interlinked evolutionary technologies.